Panama Humanitarian Project: Conjoined PVC Pipes

At the end of my freshman year I had the great opportunity to work over the summer at Villanova University on a research project funded by Harris Corporation. As part of the Villanova Summer Innovation Incubator (VSII), I worked as a member of a 4-person team focused on the creation of a new system to conjoin PVC pipes without the use of traditional couplings or flanged pipes. I had the honor of being chosen as the lead designer for the project and was able to lead the group successfully through our project over the three-month-long program.

The “Conjoined PVC Pipes” project was started with developing communities in mind, specifically the community of Cañazas, Panama, which was suffering from shortages of potable water due to the low throughput of the water system. In order to alleviate this issue, the community planned to switch their 4”diameter PVC piping to 6” diameter pipes in order to allow a higher overall flow-rate and therefore provide a more adequate amount of water to the community. Due to cost concerns, the Cañazas community was not able to buy any couplings or flanged pipes, only straight standard pipes. Due to these pipes having no way to overlap, there is no way to properly join these without a coupling, which is where this specific project comes in.

Our goal was to bypass the need for couplings by adding a flange the ends of these standard pipes ourselves. This would greatly cut down on costs, and therefore enable the community to use that money towards other projects.

While quite a variety of mechanisms for expansion were considered, the most promising was the “Radial Spreader” design. In order to be successful for our purposes, this would have to be able to not only expand the pipe to the right diameter, but also to a properly circular shape - something we found to be an issue in earlier designs.

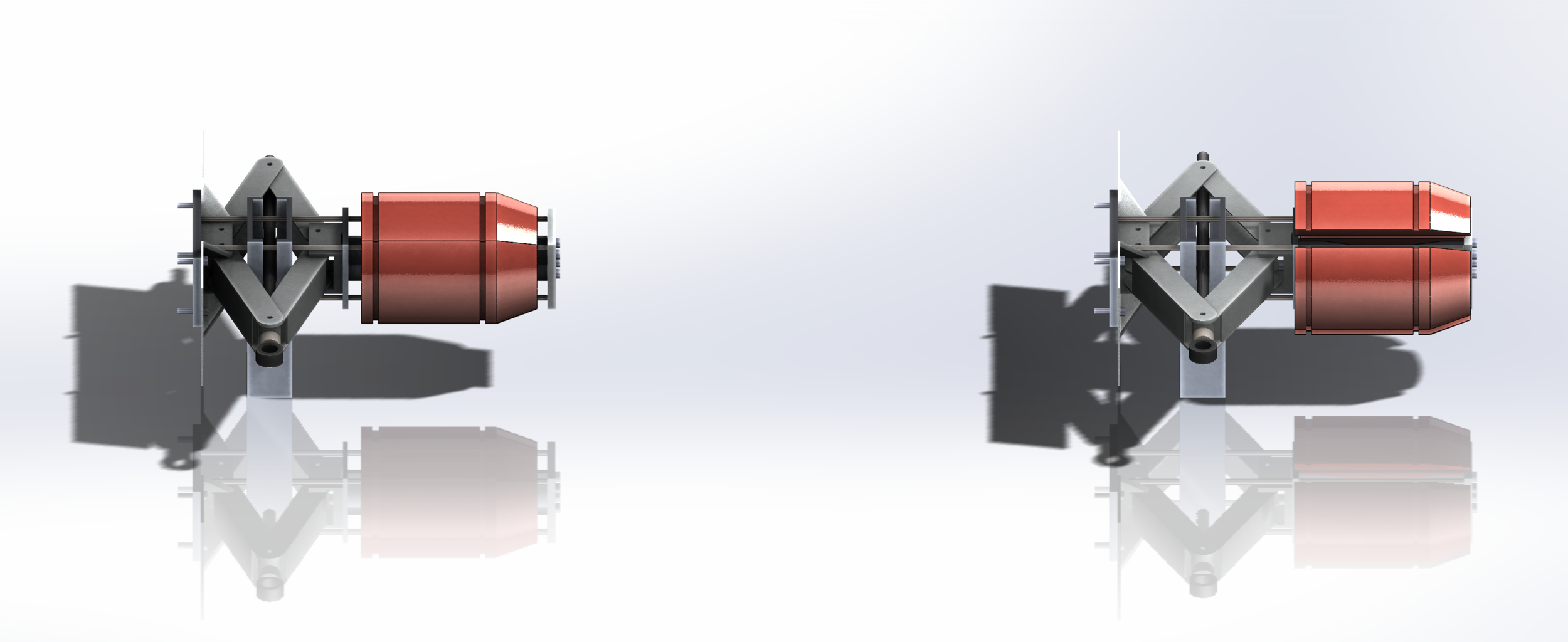

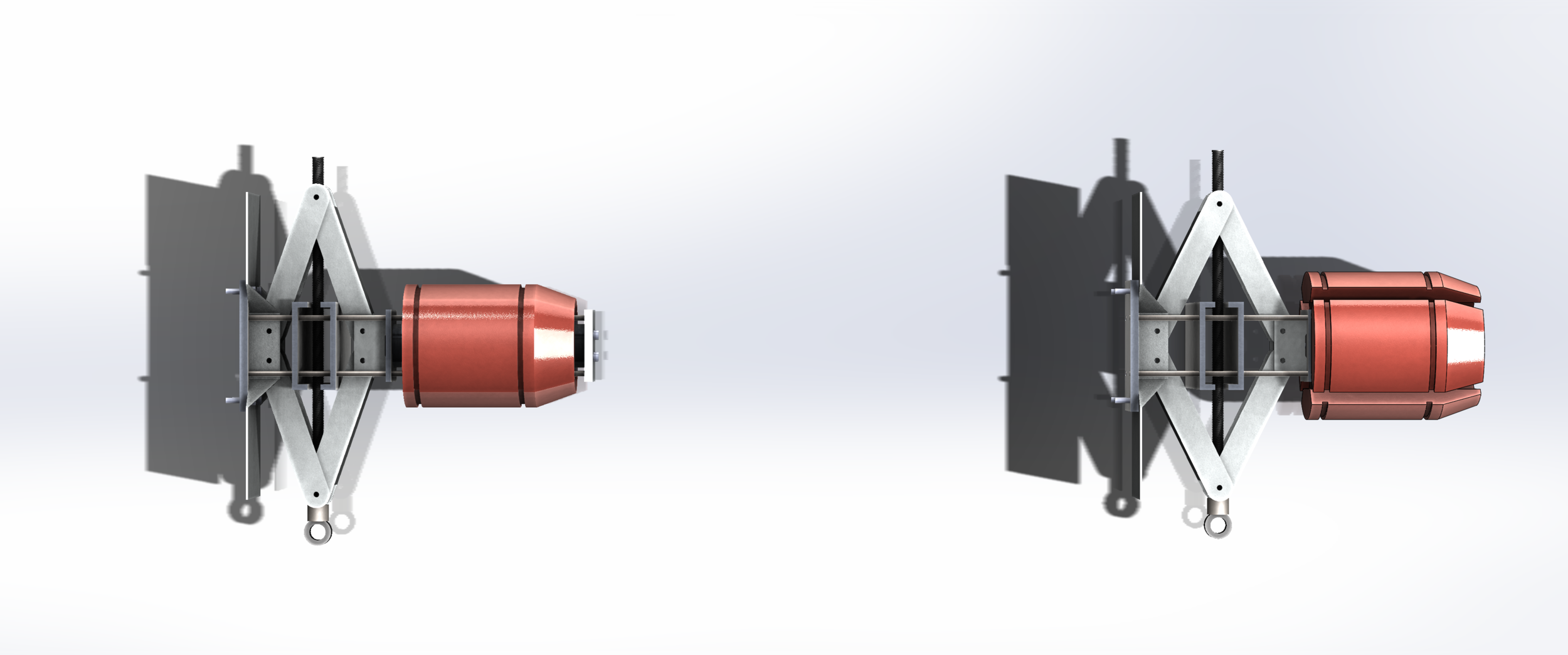

In order to accomplish this radial motion, two conical wedges are driven into four “quadrant” pieces, effectively pushing them out radially from the axis that runs down the length of the machine.

The two conical wedges were driven via the mechanics of a car jack - an option made even better considering car jack’s wide availability and low relative cost. As the hand crank is turned, the jack expands, pulling the conical wedges towards each other. These conical wedges push against the 3D printed quadrants pushing them outwards, therefore increasing the diameter across the quadrants, stretching the PVC to its new size.

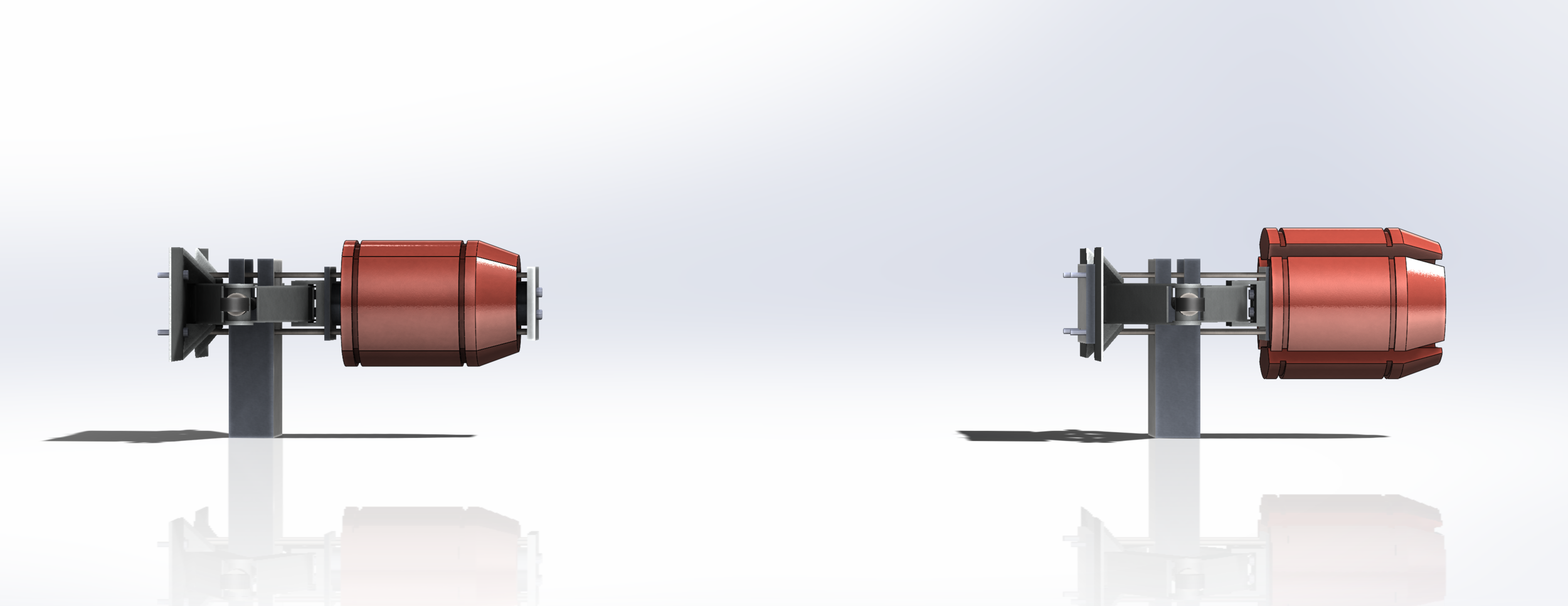

The above views show the radial spreader both in its “stowed” and “expanded” positions. Note the varying positions of either end of the car jack - this is a more immediately visible analogue for the motion of the conical wedges as they push the quadrants out.

This is perhaps the project that I am most grateful to have been a part of during my time at Villanova, as it not only broadened my understanding of the design process, but also because it jumpstarted my interest in larger-scale engineering projects. Where I had previously worked on small 3D printing projects at home, I was now working through proper design for manufacturing and tolerances. Where I had been walking, this project brought me up to a run. At the end of the day it’s projects like this, where you truly get into the nitty gritty of an issue, that get me excited. There’s just really nothing better than going from concepts in your head to a fully functional and complex manufactured product.